What Are You Looking For?

Aluminium 6082 and 6061 are two popular grades of aluminium alloys, commonly used for various applications for Truss Systsem.

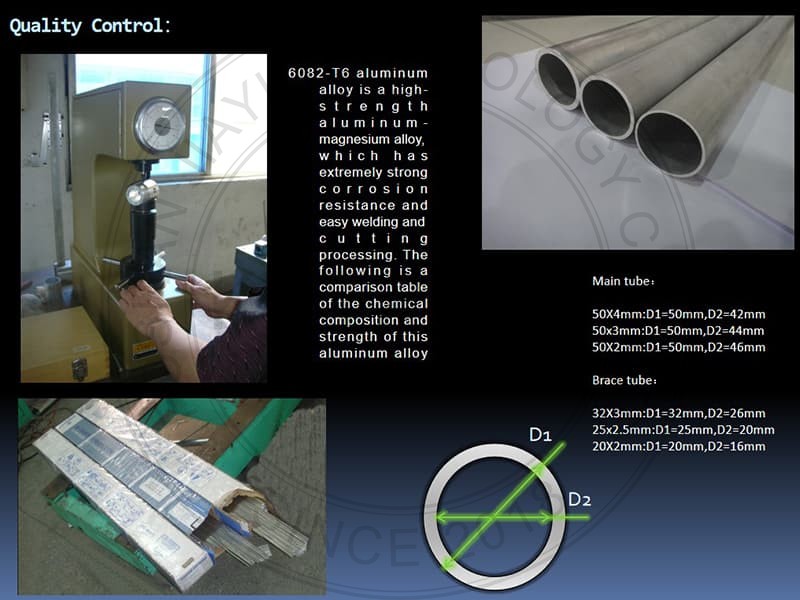

The main difference between 6082 and 6061 aluminium is in their composition. 6082 aluminium contains 97.6% aluminium, 2% magnesium, and 0.4% silicon, while 6061 aluminium contains 96.9% aluminium, 1% magnesium, 0.6% silicon, and 0.35% copper. 6082 aluminium is known for its high strength and good weldability, while 6061 aluminium is known for its good corrosion resistance and weldability.

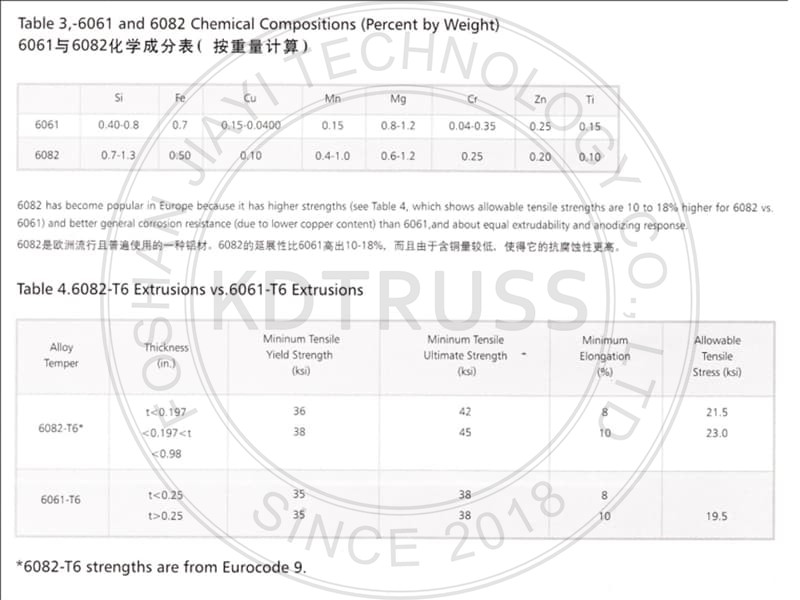

The main difference between Aluminium 6082 and 6061 lies in their chemical composition and resulting mechanical properties:

Chemical Composition:

Mechanical Properties:

It's worth noting that the specific requirements of your outdoor concert stage will dictate which alloy is more suitable. Both Aluminium 6082 and 6061 can be used for stage platforms, but factors such as load-bearing capacity, design considerations, and cost may impact the choice of alloy.

When it comes to aluminum trusses, both alloys can be suitable depending on the specific requirements of the application. Both 6082 and 6061 are popular choices for trusses due to their strength, corrosion resistance, and weldability. The selection between the two alloys may depend on factors such as the load-bearing capacity required, the design considerations, and the available budget. It is recommended to consult with a structural engineer or a metal fabrication professional to determine the most appropriate alloy for your specific use case.

Aluminium 6082 is a heat-treatable alloy with good formability and weldability.

Aluminium 6061 is a heat-treatable alloy that is also corrosion-resistant.

Aluminium 6082 has higher strength than 6061.

Aluminium 6082 is more expensive than 6061.

Aluminium 6082 is better suited for applications that require high strength

Hi! Click one of our members below to chat on